Sawmill narration

Notes on cutting up a Cherry log at the sawmill. Learning to cut for quarter sawn. Trade offs.

Hello and welcome to Hungry Woodworker, a humanistic exploration of woodworking, purpose, and making a living. I’m Taliesin and one thing I do when not working is write; some of which gets edited into essays and shared every other Thursday. Thank you for being here.

Last week, we cut up what was left of the Cherry tree that had fallen down on the woods of Dad's property. This was the third 8-foot log left and I asked Dad to talk me through cutting it to maximize quarter sawn wood.

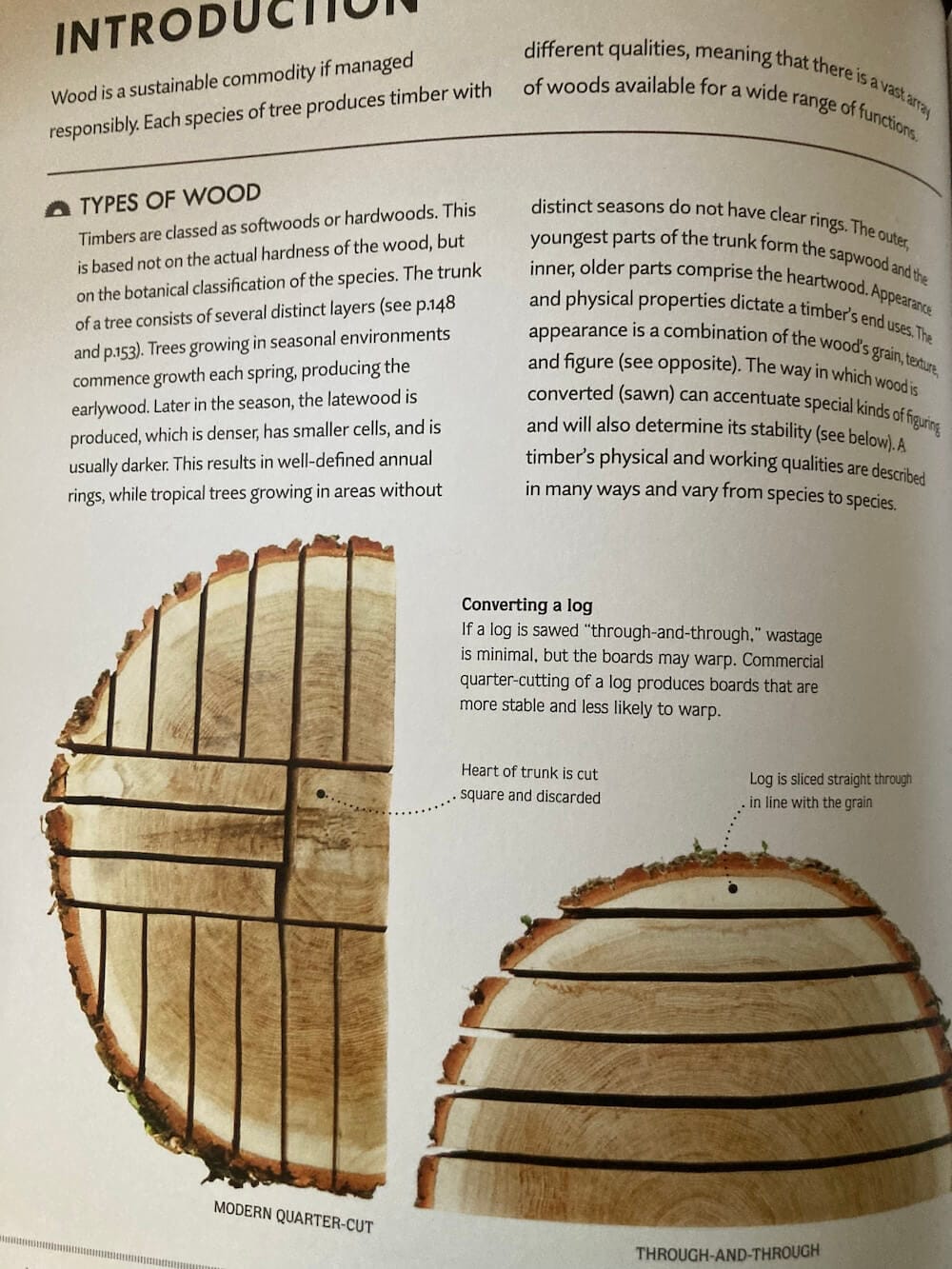

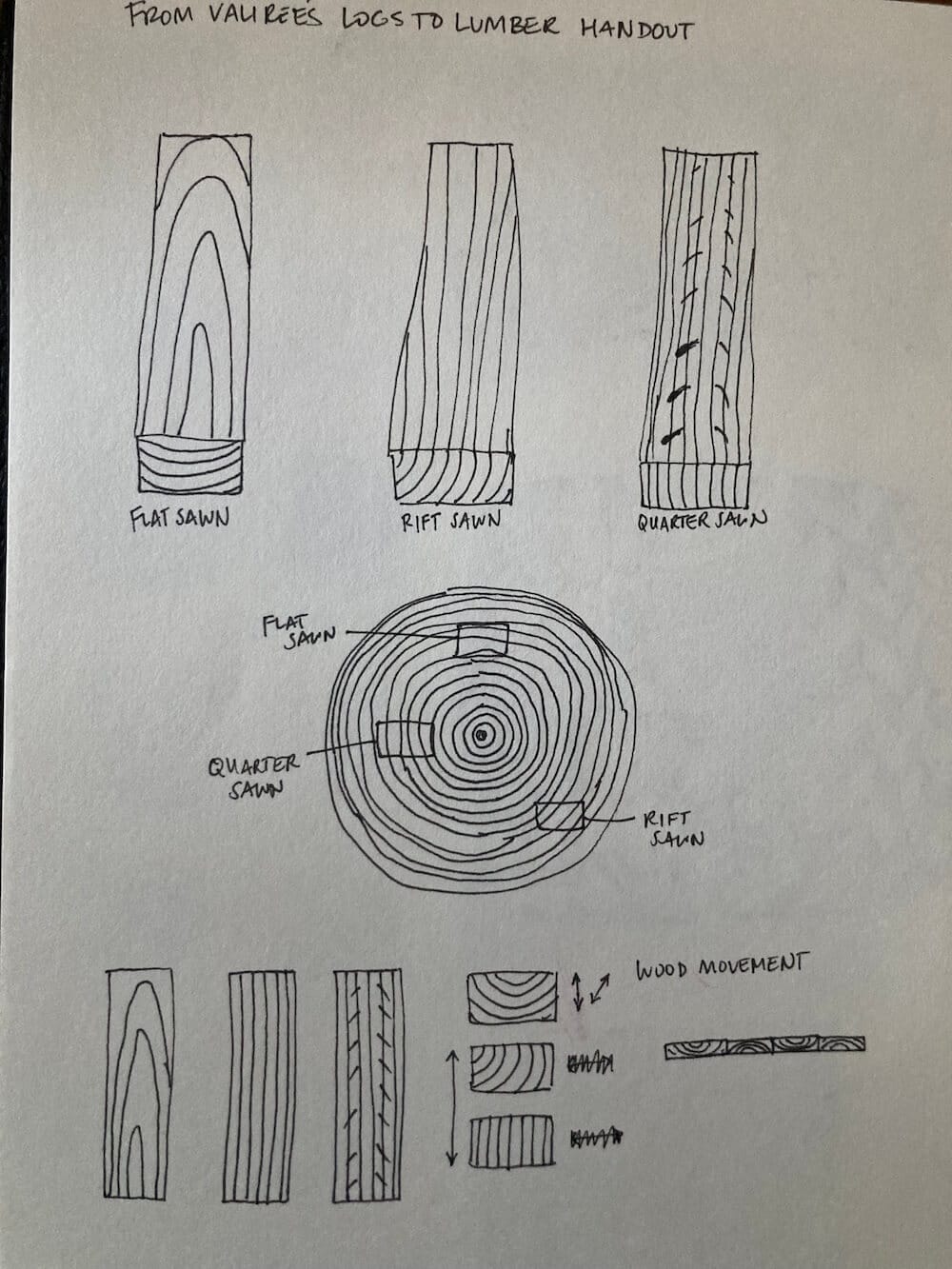

Quarter sawn lumber is prized because it's more dimensionally stable—less likely to warp or twist—and, at least in certain species, it's where you can find beautiful features like medullary rays. The wood is more stable because the grains run perpendicular to the board. An example of these rays is in the third photo—this is a cabinet I build out of Red Oak; I used quarter sawn wood for the legs and door frames to highlight the medullary rays.

I'd like to think this is a touching detail that my steadfast and charming partner Josiah noticed right away and appreciated.

The book referenced here, Woodwork: A Step-By-Step Photographic Guide to Successful Woodworking by John Lloyd, Gill Bridgewater, Sally Francis, et al., shows how a log is usually cut up to maximize quarter sawn lumber. My crude drawing was my attempt to remember all these terms and where in the log these types of cuts come from by sketching it out from an info sheet Dad shared with me.

We used the skid steer to pick up the log and put it on the sawmill. Once there, we turned it so the biggest crack at the end was basically straight up and down. That crack is the center of the log and the easiest way to get the most quarter sawn wood was to first cut the log in half and then focus on cutting up each of the halves.

After that first cut, we moved the one half over to some sawhorses. Dad told me there was a time when he would've just picked up the log and moved it by hand. Today, he says, he uses the skid steer for those kinds of things, because he no longer enjoys carting a couple hundred pounds of log from one place to the other. I've never had to pick up half a log to realize it's not something I'd enjoy.

The first cut is a skim cut to straighten out the side of the log, removing any bumps or zig zags. Then we moved the log over and cut the boards to be 1 1/8" thick. We stacked them on stickers nearby. Once we were halfway through this log, we flipped it over and did the same thing again to cut up the remaining wood.

So technically this isn't true quarter sawing, according to the book (and, well, all the woodworkers). But true quarter sawing means you're left with a chunk in the middle that is basically waste wood. Which is wasteful. And it's a lot more hassle on the cutting up side of things, as you have to be constantly turning the log, instead of setting it in one place and making all your cuts.

With woodworking—hell, with life—there are always trade offs. How much time you have to devote to doing the best or getting the best out of the resources available. What you can live with and what will stick in your craw to the point that doing or not doing it will become emotionally cancerous. What you're okay wasting and what you're not. We can't do it all, so what's going to give? And how are you going to live with yourself after that choice is made?

After the log is completely cut up and stacked, we had six pallets of lumber, enough to fill the kiln. Sometimes Dad air dries wood, sometimes he uses the kiln. It depends on when he will need the lumber and what it is likely to be used for. We put cement blocks on top to encourage the lumber to stay flat. The whole thing gets closed up after the fans are turned on and there the wood will sit, curing like wine in a barrel for around three months. Once the moisture content of the wood is down to around 10%, we'll bring it out and begin the process of trying to find a place to store it.

Nothing in woodworking is ever very quick.